Department of Fluid Machinery and Engineering in Xi’an Jiaotong University was established in 1956 which was the earliest teaching and research organization for axial and centrifugal compressors in China. The master degree authorization was granted in 1957, and the doctor degree authorization on Fluid Machinery and Fluid Engineering are granted in 1981. Fluid Machinery and Engineering was regarded as the national key discipline in 1988. The National Key Laboratory of Fluid Machinery was accredited in 1989. The National Engineering Research Center of Fluid Machinery and Compressor was accredited in 1995.

With long history, the department has 30 teaching and researching staffs, including 11 professors and 12 associate professors, 1 research fellow and 1 lectures, 3 senior engineers, and 2 engineers. Among all scholars, one person is awarded as the distinguishing young scholars from the National Natural Science Foundation of China, one person is selected as the cross-century excellent talents by the Ministry of Education, and five persons are selected as the new-century excellent talents by the Ministry of Education and one person become “Hundred Excellent Ph.D. Dissertation Receiver”, another three persons won the honors of “Excellent Doctorial Dissertation of Shaanxi Province”.

Research Interest and Area:

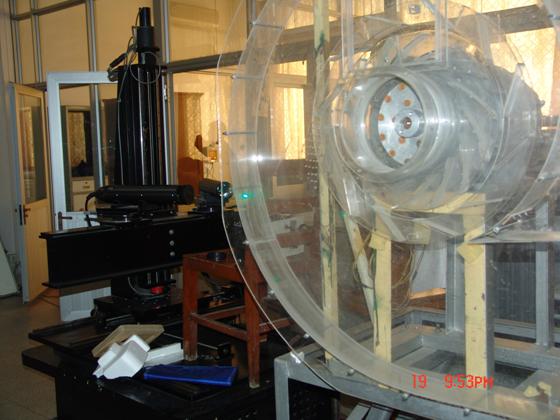

(1 1. Theoretical and Experimental Study on Fluid Machinery

(a) Unsteady flow in fluid machinery;(b) Flow mechanics and key technique for micro-scale centrifugal compressor; (c)Fluid-structure interaction in macro-scale fluid machinery;(d) Flow control technique for fluid machinery; (e) Thermodynamic computation of real gas in centrifugal compressor; (f) Aeroacoustics of fluid machinery and noise control technique; (g)Non-linear dynamic model of flow;(h) High performance numerical method for flow simulation.

2. Design Method, Control Technique and Engineering Application for Macro-scale Turbomachinery

(a) Advanced design method and key technique of energy saving for fluid machinery; (b) Multi-discipline optimization method and advanced optimization algorithm; (c) Multi-stage match technique of multi-stage compressor; (d) Stall and chock prediction method for compressor system; (e) Drag reduction method of centrifugal impeller with high pressure ratio and low flow coefficient.

3. Complex flow in Micro-scale fluid machinery and fluid engineering

(a) Microscopic dynamics and macro scattered body dynamics analysis on the scale conversion of sand flow; (b)Theory and experiment research on the energy output and stress distribution in the flow field of gas bubble in under water explosion; (c)Micro-PIV based experimental investigation on microscale flow and microscopic model; (d)Optimization on the mechanism and structure of micro-flow in mechanical heart valves; (e)Complex flow in directional solidification process for multi-crystalline silicon ingot and transport mechanisms of various chemical gases and impurities in high temperature furnace.